// independent stave company //

Family-owned for over 110 years

Four generations of the Boswell family have built ISC into a global cooperage leader. From our stave mills to our cooperages, we craft barrels through sustainable practices and innovative technology. As a result, millions of people around the world enjoy beverages aged in ISC barrels.

Photo: Independent Stave Company fourth generation owners and siblings Joe Boswell, Amie Boswell Dewane, and Brad Boswell

Crafting an ISC Barrel

The craftsmen at our stave mills and cooperages are the heart of Independent Stave Company. Their skills turn quality oak into barrels for the World's Finest Spirits.

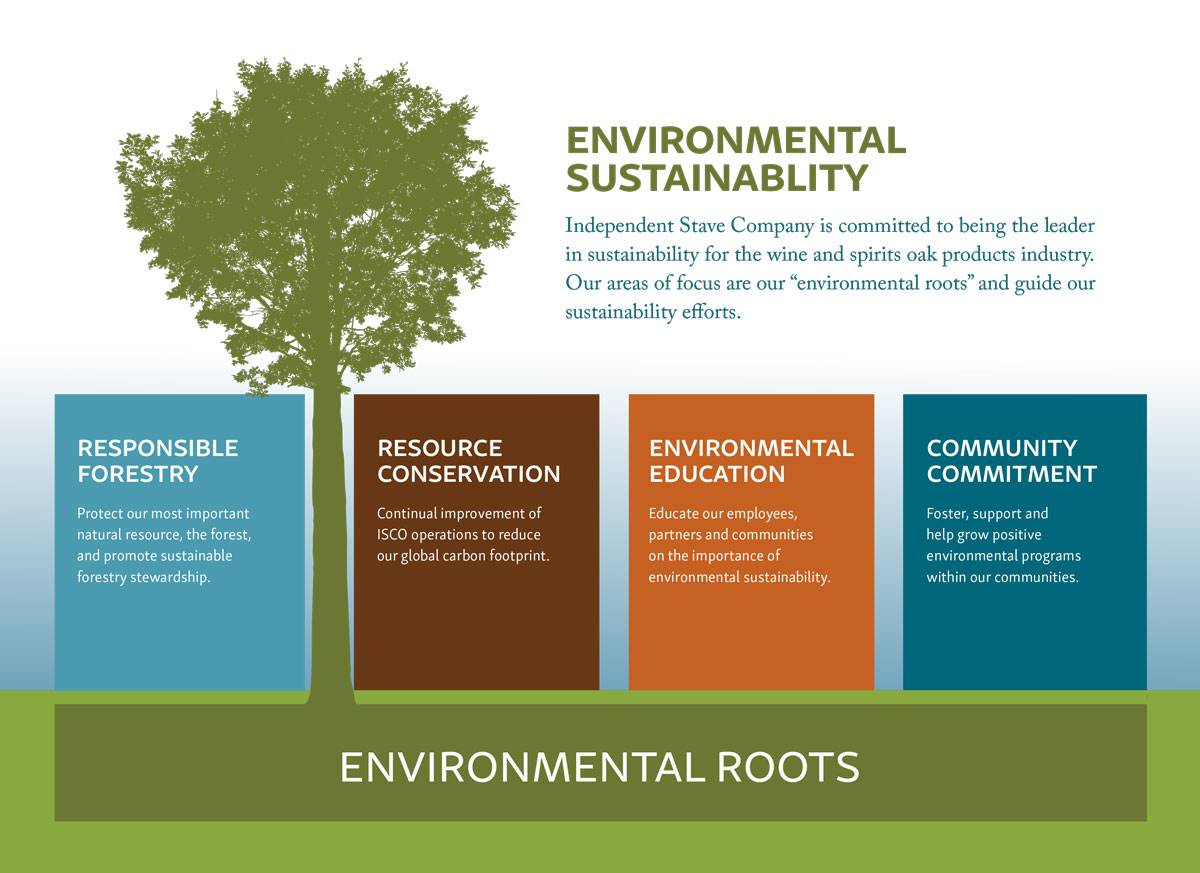

// sustainability + harvesting //

Taking care of our most valuable resource

In crafting premium oak barrels, Independent Stave Company is dedicated to ensuring healthy, productive forests that will continue for generations to come. We are committed to only using oak that has achieved a sustainable certification.

In 2022, our domestic stave mills and cooperages achieved certification to the Sustainable Forestry Initiative® (SFI). Today, all American oak barrels manufactured domestically are certified to the SFI Fiber Sourcing Standard.

We believe education and outreach through land and process certification is one of the most effective and manageable solutions to achieve sustainability.