From Forest to Barrel: the Stave Mill

At our six domestic company-owned stave mills, employees take the high-quality white oak logs and process them into rough staves utilizing 100% of the log. Material that cannot be used for staves is converted into a variety of natural products such as chips, mulch, and sawdust.

Our finished product – a rough stave – is cut with exact specifications to give our cooperages the opportunity to make world-class oak barrels without unnecessary wood loss during the process.

Making a Rough Stave:

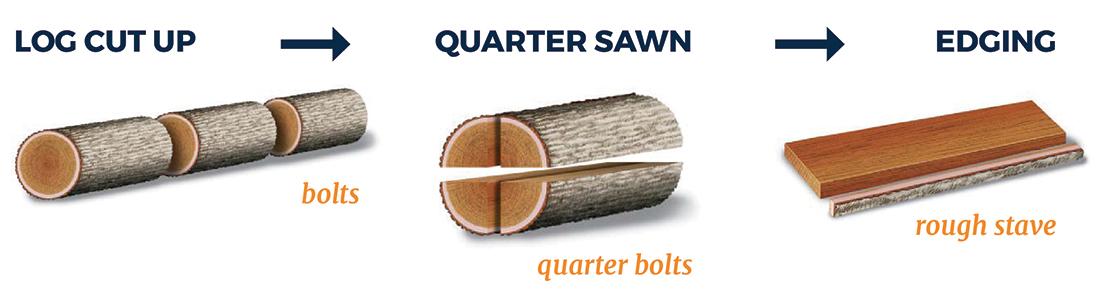

The journey from log to rough stave begins at the log deck. Logs are processed into bolts, quarter bolts, and finally rough staves.

Each stave and heading piece is individually inspected and stacked according to its intended use. Finally, quality control technicians inspect the material ensuring each piece meets quality standards before it is sent to our Missouri Cooperage or Kentucky Cooperage.

Stacking quarter bolts

Processing oak into rough staves

Stacking rough staves

Stave quality control inspection

Meet one of our Stave Mill Managers:

Mike Knudson, Morehead Wood Products Mike Knudson’s first job with ISC Barrels (at Missouri Cooperage in Lebanon, MO) was working on projects while he was in high school. He continued working part-time through his senior year in 1997, and after graduation was hired full-time as a Purchasing Agent Assistant at Missouri Cooperage.

Mike Knudson’s first job with ISC Barrels (at Missouri Cooperage in Lebanon, MO) was working on projects while he was in high school. He continued working part-time through his senior year in 1997, and after graduation was hired full-time as a Purchasing Agent Assistant at Missouri Cooperage.

From 1997 to 2014 Mike worked front-line production jobs, quality control and eventually managed both the stave and heading departments.

In 2014, Mike shifted course and began training to become a stave mill manager. After training at company-owned mills in Missouri and Ohio, he oversaw the construction and installation of Morehead Wood Products in Morehead, KY and was named Stave Mill Manager when production began in August 2015.

Morehead Wood Products was built with state-of-the art, proprietary technology, developed by our in-house engineering team.

Notes from a Stave Mill Manager:

What type of employee environment do you cultivate at Morehead Wood Products?

“I want Morehead Wood Products to be a place where employees want to come to work. Yes, they're coming to earn a good paycheck, but my goal is to make the environment a place people feel valued and enjoy. In my experience, employees who want to come to work will work harder because we make it a great place for them to be.”

How do you promote safety in the Stave Mill?

“We try to create a culture of safety-minded employees. We educate them on the top recordable incidents and what we as a group can do to be better and safer. As an employer, it is our responsibility to minimize both unsafe environments for employees to work in and unsafe acts that employees might engage in. We want our employees to know that they play a big role in creating a safe environment for themselves and their fellow employees.”

How is Morehead Wood Products involved in the surrounding community?

“A big emphasis is placed on charitable support and community involvement in Morehead. It gives our employees a sense of pride in the company they work for and makes a difference for their family and friends who live in Morehead. From an economic standpoint, I also like being a larger employer in the community. Whether it is the 200-300 log suppliers we work with or the trucking companies that haul our products or the people who mow the grass around our facility - we are truly integrated into the Morehead community.”

What role does technology play in the stave mill?

“All ISC stave mills – like Morehead Wood Products – focus on continual improvement. We consistently implement improved technologies and processes. Our proprietary technology is built by in-house engineers specifically for crafting quality bourbon staves which translates into quality bourbon barrels. This industry is all about integrating the latest technology with traditional craftsmanship - at the end of the day, our staves are still crafted by people.”

Comments 3

Great company in an exciting industry!

Morehead KY is very proud to have ISC’S Morehead Wood Products in our community! Profession operations with a strong commitment to the area.

Thank you for being here!

Pingback: From Forest to Barrel: Stave Finishing | ISC Barrels

My father ran a stave mill in Princeton, Ky. When I was a young boy. I worked at the mill with him on Saturdays. I busted stave bolts with hammer and wedge for extra money. I got to do most of the jobs at the mill during summer break. All hard work. Reason I was researching this is because we never see trucks hauling bolts anymore so I wondered if people still busted them with hammers. Hard to explain the work to someone that has never done it but I will never forget it. I’m 68 years old now and can remember the those big white oak staves, guys called them bible leaves. Thanks for letting me look at your process.