From Forest to Barrel: Stave Finishing

After rough staves are made at our company-owned stave mills, they undergo seasoning and air drying. American oak is seasoned at our domestic stave mills while our French and European oak season at our stave mill in Monthureux-sur-Sôane, France.

Our cooperages maintain a large inventory of seasoned wood to meet the varied demands of our customers. Once staves have reached the customer specified natural seasoning length, they are dried to the appropriate moisture content for barrel production.

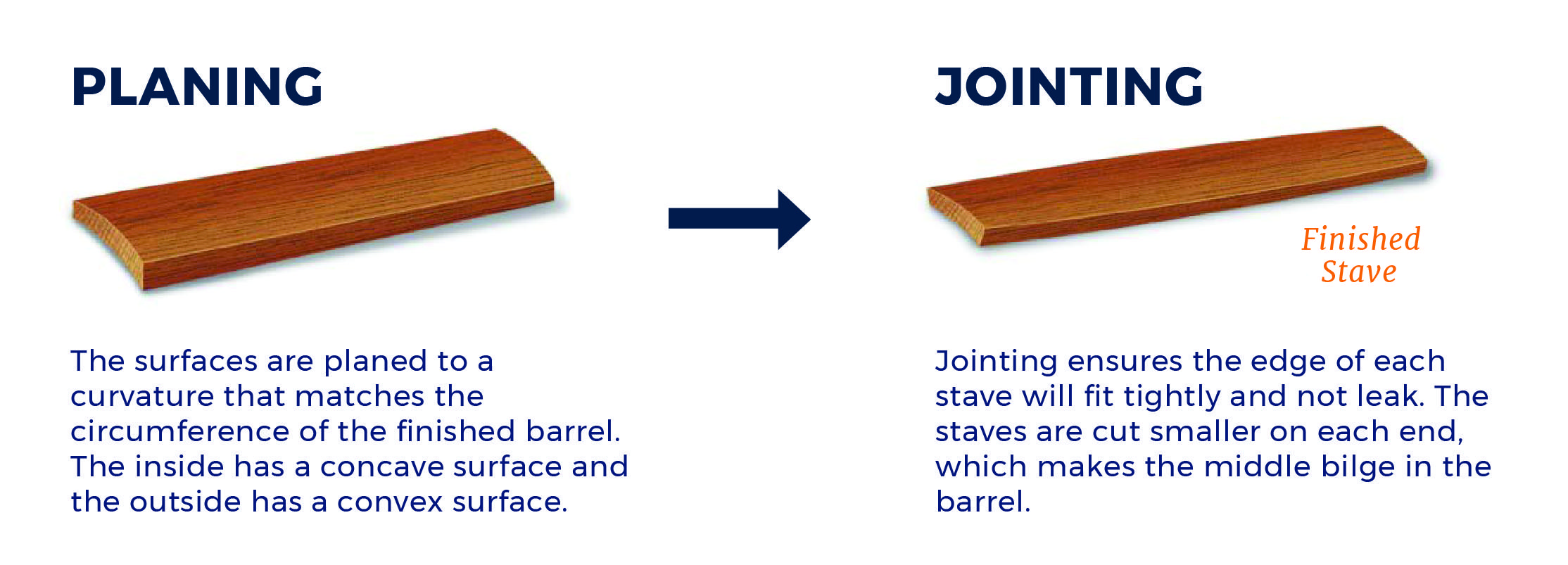

Dried staves are first processed through equalizer saws which cut them to the desired length for spirit barrel production. The staves then pass through planers which create the convex curvature on the exterior surface that matches the circumference of the finished barrel. The interior is finished with a concave surface.

The jointers are set with precision to ensure correct bilge size and angles. Barrel raisers arrange jointed staves in a set-up stand which ensures a consistent amount of wood is used in each barrel. The combination of wood amount and joint shape determines the final size and shape of the barrel.

After being raised, barrels are placed on a conveyor passing through a steam tunnel. The steam softens the fibers in the wood making it pliable for the bending process which takes place in the Barrel Assembly Department.

Get to Know Kentucky Cooperage

Brian Lanham, Stave Department Supervisor

I started working in the Stave Department for Kentucky Cooperage in 2004, reporting to Barry Shewmaker, who was Stave Department Supervisor at that time (he's now Kentucky Cooperage Plant Manager). I worked diligently to learn the Stave Department from the floor up by working in various positions - from Stave Jointerman to Planer Operator to Quality Control and more. In 2011 I was appointed the Stave Department Supervisor.

It's the Stave Department's job to make sure raised barrels sent to barrel assembly are produced within specifications. Our Quality Control Team inspects random samples in various areas throughout the entire department; monitoring and measuring processes which include both the operators and machining equipment. These quality inspections ensure barrels leaving the Stave Department are within internal manufacturing specifications.

In the Stave Department we maintain a safe, goal-oriented environment by setting smart goals, tracking our progress and rewarding and celebrating our accomplishments. Through this mindset, every employee in the department clearly understands the value of safety, quality and efficiency.

Brian Lanham

Stave Department Supervisor

Kentucky Cooperage