First Barrel Experiment Rolls into the Boswell Family Warehouse

By Andrew Wiehebrink, R&D Spirits Division

Earlier this year ISC was on hand for the first barrel fill at the James B. Beam Institute. Now, I am pleased to share that the first barrel experiment is currently resting inside the Boswell Family Warehouse on the University of Kentucky campus.

ISC Barrels resting inside the Boswell Family Warehouse for first JBBI student experiment.

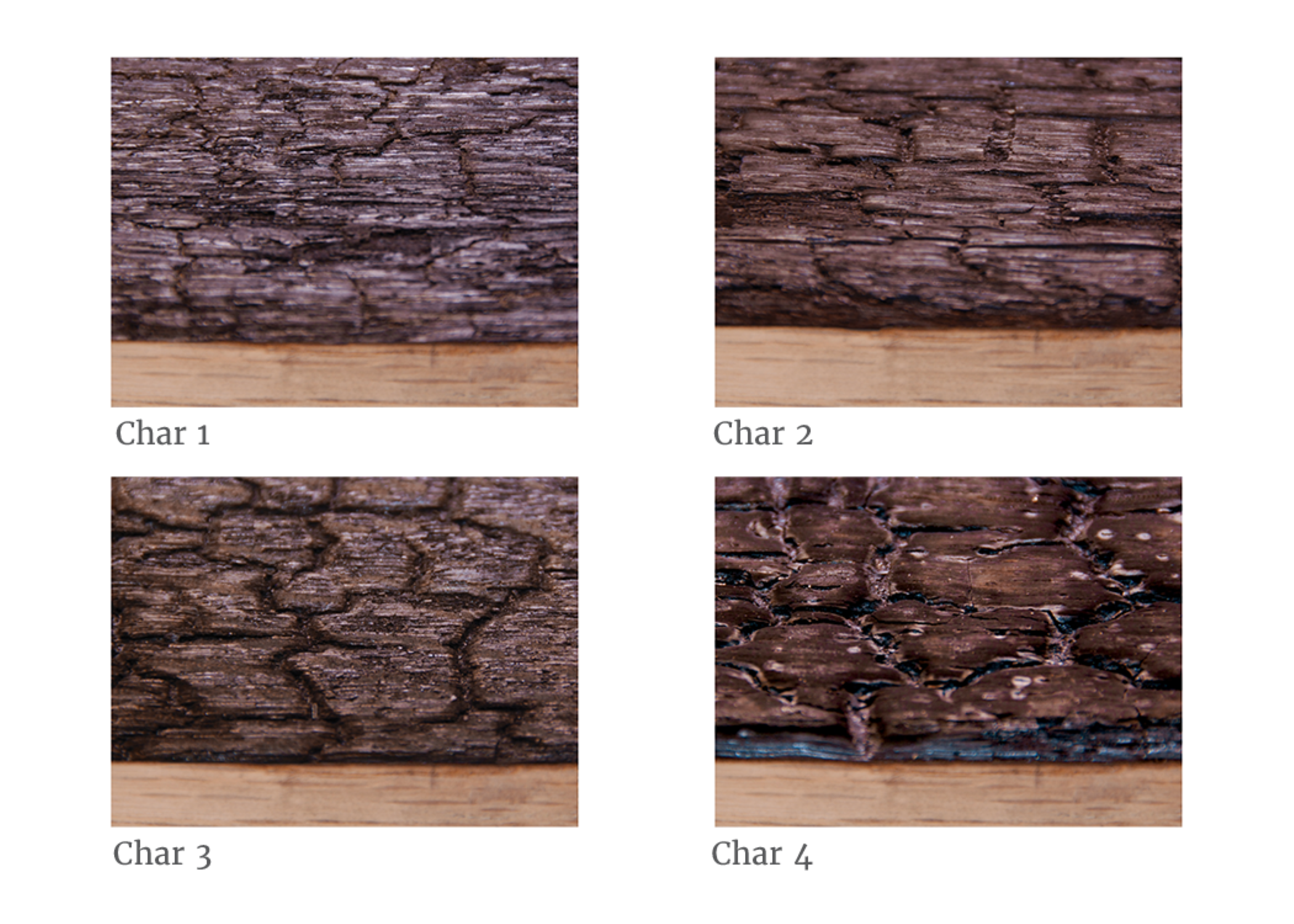

When Dr. Seth DeBolt, Institute Director, and I spoke about what type of barrels should constitute the inaugural experimental batch, we quickly landed on a char level experiment given the fact that charring oak barrels is one of the foundations of bourbon. (Next to watching new make distillate flow through the spirit safe, it is perhaps the most visually captivating and arguably the most well-known aspect of bourbon production.)

Char level creates flavor by degrading two components that essentially make up 50% of the oak wood: hemicellulose and lignin. When these components degrade, they will degrade in a way such that more favorable aromas and flavor components are formed. That degradation is a function of temperature, and we refer to this process of creating flavors by destruction as a “degradation chain”. This in essence is what the students will be dissecting.

By learning more about how these two oak components degrade as a function of heat (pyrolysis), the idea is that we can learn more about flavor production and how to target specific flavors using heat as the main source of component destruction.

Over the next four years, students will be able to monitor the progress of eight barrels and learn about the complexities of oak maturation from the liquid that they themselves will gather and then analyze. These barrels will serve as a solid foundation for future experiments to come.

- (2) 53 gallon, American White Oak, Char #1 barrels

- (2) 53 gallon, American White Oak, Char #2 barrels

- (2) 53 gallon, American White Oak, Char #3 barrels

- (2) 53 gallon, American White Oak, Char #4 barrels

With each of the four char levels represented, students will aim to determine what flavor and color differences arise from altering the char level, as well as how depth of char affects subtraction, evaporation, and oxidative reactions.

Charring of the oak barrels is necessary on many levels. It is a complex reaction that is necessary to produce the color of the spirt, it is necessary to produce robust flavors, and it is even necessary from a legal standpoint as the process is mandated by the federal government. That’s right. To be bourbon, you legally…HAVE TO DO IT.

Students have embraced this project and their excitement around what’s to come has already begun to build. Duncan Gregory, a student in Chemical Engineering and DWB Certificate (Distillation, Wine and Brewing Studies), shares that he is “really looking forward to seeing how the flavor and profile of the product is affected," while Zac Lockhart, student in Chemical Engineering and DWB Certificate explains, “It is common to see different distilleries using the same types of charred barrels. Learning about the influence of the char level can create new tastes in the spirits and create a new appeal to consumers.”

Dr. DeBolt adds, “The product coming out of the Institute and the Boswell Family Barrel Warehouse is not the whiskey, it is the next generation of distillery workforce. With this char level project students will learn replication, data acquisition, monitoring, quality evaluation and how to communicate their findings.”

Charring is a critical component of barrel making and all of this comes together for a natural place to land as the cornerstone experiment in the Boswell Family Warehouse. Undoubtedly, the data being gathered from this experiment will be used to generate classroom learning material and presentations. Most importantly, I hope it generates more questions that need to be answered by means of more experiments.

More on this next year!

Cheers,

Andrew Wiehebrink

Comments 4

Sounds like a great research project! I’m curious if there have been studies analyzing the flavors produced by different white oak species like overcup, swamp, chinkapin, and chestnut. Do you have any info on that?

Hello Malcolm. Thanks for the question.

We have done some internal testing on different wood species, including oaks from North America and beyond. At this point we haven’t put together any formal compilation of the data or our conclusions.

Nice.

Thanks Ramona!