Studying Maturation Dynamics with our Environmental Chamber

by Andrew WiehebrinkAt Kentucky Research Center, most of our efforts are geared towards sensory analysis, customer product development and flavor discovery. However, thanks to a new piece of equipment that we acquired earlier this year, we can now study another very important aspect of barrel aged spirits: maturation dynamics.

Dynamics is defined as ‘the properties that stimulate change within a system or process’. In the case of our new environmental chamber, the properties we are changing are temperature and humidity.

Kentucky Research Center Environmental Chamber

Both properties are important aspects of maturation. Humidity has an influence on what components are leaving the barrel as the liquid evaporates. To put it simply, will it be water or alcohol that evaporates1? Humidity also has an effect on the oxygenation process since the diffusion of oxygen varies depending on the media (air or water) through which it is being diffused. Temperature, on the other hand, seemingly has an effect on just about every aspect of barrel maturation. The solubility of compounds, extraction rates, oxygenation, evaporation, and even humidity itself.

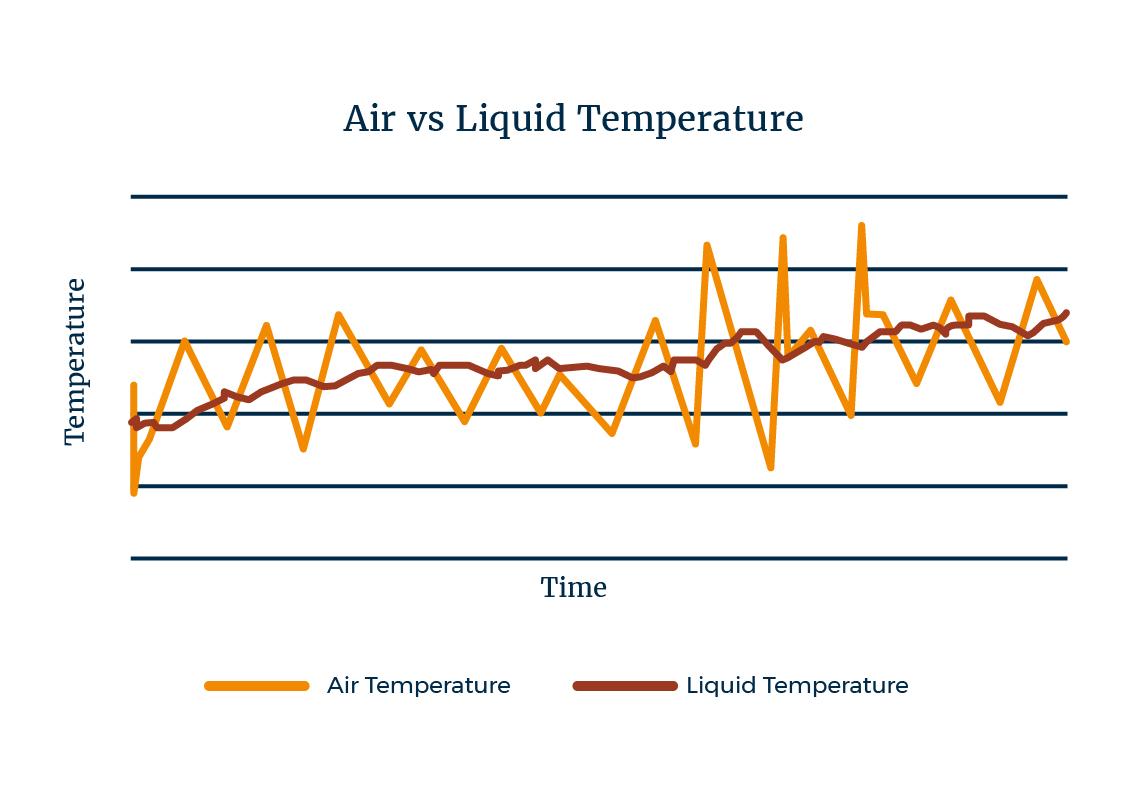

Most importantly, it directly affects the rate at which the spirit moves in and out of the oak, or what we call ‘cycling’. Cycling is dependent on pressure changes and pressure changes are a direct result of a change in temperature as validated by the equation PV = nRT (ideal gas law).

Our environmental chamber allows us to fluctuate the internal temperature from -20F to 130F and we can move from one extreme to the other in less than two hours. It also allows us to fluctuate the humidity from 5% to 95% depending on the temperature inside. Additionally, we have the capability to program a virtually unlimited number of set points for both temperature and humidity into the controller. This means we can take warehouse temperature data, theoretical or actual, and program the data points into the chamber. In other words, we are able to create or recreate just about any aging environment imaginable. We can study specific days, or we can study specific years.

Even with this small sample, we can see some interesting relationships as the air temperature rises and falls. Upon completion of this experiment, we will be able to better understand how our barrels are going to contribute flavor to various spirits.

Not only will we be able to study the mechanical dynamics of barrel maturation, but we will also use this piece of equipment to develop new toast profiles, study new wood species, test new products, etc. The purchase and implementation of this chamber further solidifies Independent Stave Company’s commitment to study all aspect of barrel aging. It is all part of our effort to be a leading source of information to all our customers around the world.

1Water and alcohol aren’t the only things leaving the barrel as a result of evaporation.

Andrew Wiehebrink

About the Author

Andrew joined the ISC team as the head of Research and Development in early 2016. His primary focus is working with ISC customers to develop and test new products. He will also design experiments to gather data on whiskey maturation, barrel performance, process and product innovation.

As a self-described, "bourbon fanatic" Andrew enjoys drinking and studying the history of bourbon. He also owns and operates a farm in Oldham County Kentucky that develops custom corn breeds for use in distilling.