What ISC’s Barrel Trials Mean for Bourbon Producers: Practical Takeaways You Can Use Today

By Andrew Wiehebrink, Director of Spirit Research and Innovation

With last year’s Research Series- as published in our book ‘A Comprehensive Collection of Independent Stave Company Research: Oak & Its Influence on Spirits’- we set out to answer a deceptively simple question: what really happens inside a bourbon barrel? Not in theory. Not through tradition or assumption. But through measured trials. We shared 10 trials ranging across topics such as seasoning, char level, warehouse conditions and oak species.

Individually, each trial told a focused story, but taken together, they revealed something larger. Barrel design is an interconnected system, where small choices interact, compound, and ultimately shape flavor development, maturation rate, and consistency.

One of the earliest insights emerged from examining char levels in Trial 1: Effect of Char Level on the Flavor Development of Bourbon Whiskey and Trial 2: Effect of Char Level on Extraction Rates in New Oak Maturation. While heavier char is often associated with bolder flavor, the data showed that lighter char levels can allow greater early access to sweet oak extractives such as vanillin and furfural. Moving from a Char #4 to a Char #1 produced up to a 13% increase in overall flavor concentration, driven primarily by these sweet aromatics meaning that a thinner char layer allows for quicker access to desirable components and the less intense heat allowed for greater preservation of sweeter extractives that are formed at lower temperatures. Heavier char plays a critical role in filtration and chemical transformation, and we still strongly suspect that heavier chars provide a greater environment for prolonged micro-oxygenation.

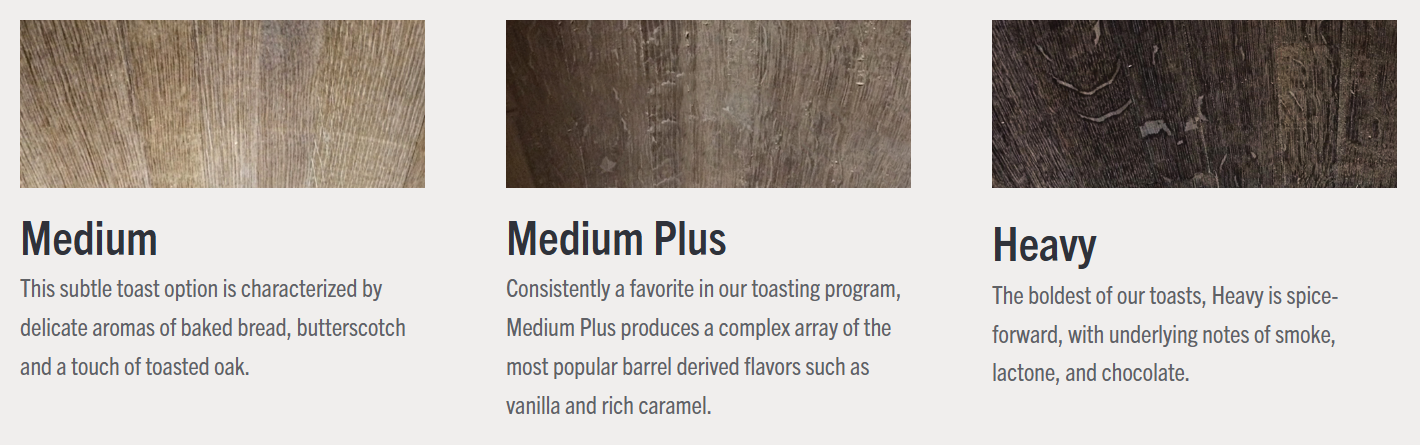

While charring is a crucial step for both flavor development and reaction chemistry, toasting allows for the controlled formation of copious amounts of oak derived flavor components as made clear in TRIAL 6: Effects of Toasting on Barrel Extractive Concentrations. Across multiple toast profiles, toasted barrels consistently produced higher concentrations of extractives than char-only barrels of the same age. Slow, controlled heating prior to charring altered the stave’s internal structure, generating higher compound concentrations which do not form as efficiently under rapid, high-heat conditions alone.

Just as importantly, different toast profiles produced distinctly different flavor profiles. Some emphasized spice, while others leaned toward sweetness. Toasting was not merely accelerating extraction; it was directing it. Trial 6 underscored toasting as the most precise tools available for shaping flavor trajectory.

Trial 3: Effect of Wood Seasoning on Extractive Concentration in Bourbon Whiskey discussed the benefits of oak seasoning and reinforcing a principle coopers have long understood but rarely quantified: seasoning matters not only for tannin reduction, but flavor production. Extended outdoor seasoning of staves consistently resulted in higher extractive concentrations in aged whiskey. Going from our standard seasoning time of 3-6 months to our 18-month material resulted in about a 28% increase in overall flavor concentration. Trial 3 demonstrated that seasoning is not a background variable, but a foundational step in the maturation process.

Trial 4: Examination of Extraction Rates and Lactone Levels in Bourbon Whiskey for American, European and French Oak broadened the scope further by examining how oak species affects extraction rates and lactone development, comparing American, European, and French oak. Chemically, American oak showed higher concentrations of oak lactones over time. These compounds are commonly associated with coconut and sweet oak character. However, the trial also revealed an important distinction between analytical data and sensory perception. While lactone levels were detectable in all the oak species, early sensory differences were not always pronounced. Meaning that while oak lactones are an important part of whiskey flavor, time is crucial as it does take several years for the levels to exceed the threshold of perception.

Environmental conditions took center stage in Trial 5: Barrel Warehousing- Effects on Maturation in a Multi-Story Rick House After 12 Months of Aging, which examined barrel placement within a multi-story rickhouse. The dominant factor was not average temperature, but the fluctuation of temperature with respect to amplitude and frequency. Barrels exposed to greater and more frequent thermal swings exhibited faster and deeper interaction between spirit and wood. These fluctuations repeatedly drove whiskey into and out of the stave, creating momentum that accelerated the extraction process. Trial 5 reframed warehouse placement as an active tool, one that can be used intentionally as part of an aging strategy.

Physical barrel design became the focus in Trial 7: Evaluating the Effects of the Small Batch Wave Stave Barrel on the Flavor Development of Bourbon Whiskey. Barrels with increased internal surface area showed immediate and sustained increases in extraction rate and concentration. The most notable outcome was not just speed, but predictability. Increased surface area produced consistent, repeatable results, reinforcing geometry as another lever producers can pull to manage maturation pace.

The final set of trials- Trial 8: Extraction Study Over 24 Months in a New Oak Double Barrel Application Using Two-Year-Old Bourbon Whiskey, Trial 9: Finishing Two-Year-Old Bourbon Whiskey in New Oak Barrels Treated with a Proprietary Cold Smoking Process, and Trial 10: Exploring Contact Time and Dosage Rate with Oak Alternatives to Achieve Targeted Sensory Results in Whiskey shifted our attention to finishing techniques, including double-barreling, smoked barrels, and oak alternatives. Across these studies, a consistent pattern emerged: most changes occurred very quickly. In the double-barrel trial (Trial 8), most of the extractive impact happened within the first few months. Trial 9 showed that smoked character could be layered efficiently atop existing toast profiles and peak levels could be reached in as little as 10 weeks. Trial 10 reinforced the same lesson with oak alternatives- dosage and contact time mattered more than extended exposure.

Collectively, the finishing trials demonstrated that finishing does not replace traditional aging. When used correctly, our wide variety of barrel products allows producers to layer flavor with precision and purpose in a very short amount of time.

Summary

We hope that the trials provide a basic understanding for some of the different flavors levers available when designing a barrel. Singularly each one has its purpose, but all are constantly working together to achieve the desired flavor profile at the end of the maturation period. Our work continues with research into oak maturation and 2026 will be an important year for our efforts. We will expand our experimental barrel program to cover aspects of maturation we have not had a chance to study.

For more information on the trials or for custom barrel design, please contact me to discuss your unique barrel solutions. I will be happy to help!

Read all 10 trials, view graphs and supporting data online at www.iscbarrels.com/blog.

Books are available through your account manager.

Andrew Wiehebrink

Director of Spirit Research and Innovation