Trial 9: Finishing Two-Year-Old Bourbon Whiskey in New Oak Barrels Treated with a Proprietary Cold Smoking Process

By Andrew Wiehebrink, Director of Spirit Research and Innovation

Introduction

There are a handful of compounds found in barrel-aged spirits that are responsible for smoky flavors and aromas. These components are not only important contributors to the overall flavor profile, but smoky aromas in high concentrations are sought after for many product categories.

Knowing this, we have introduced a proprietary cold smoking process designed to increase the barrel’s impact on smoke character in higher concentrations than previously allowed by toasting and charring. This method gives producers greater control over the flavor profile and provides a more efficient means of adding smoke character to the product.

Objective

The purpose of this experiment is to study the effectiveness of using smoked barrels in a double barrel application as a means of adding different variations and intensities of smoke character to bourbon whiskey. Additionally, we will examine if time spent maturing in the secondary barrel is proportional to smoke component concentration.

Methods

Base Liquid

Variety: 2-year-old bourbon whiskey

Mash Bill: 74% corn/14% wheat/12% malted barley

Entry Proof: 100 proof/50% ABV

Trial Execution

Entry Date: October 2020

Secondary Maturation Period: Up to six months

Warehouse Location: Traditional Rickhouse, Fort Worth, TX

The Trial

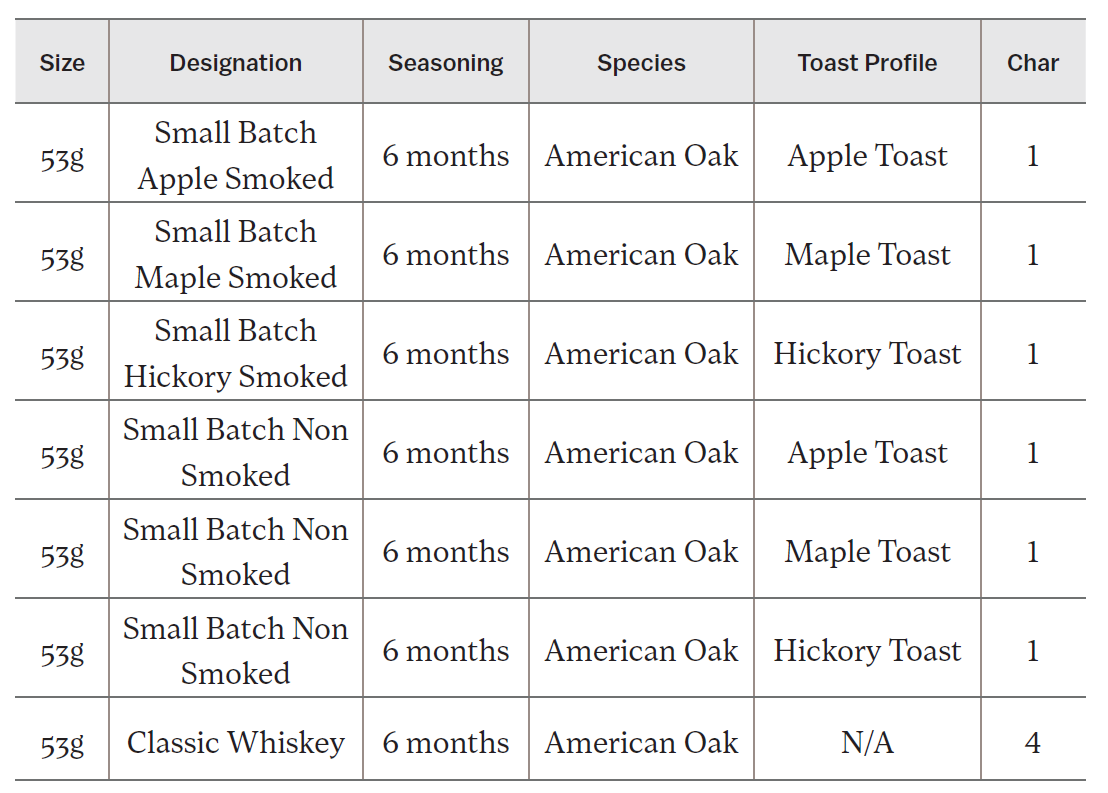

Two-year-old bourbon whiskey which was double barreled for six months in the following barrels:

Three barrels of each variation were included in the experiment.

Samples were taken from each barrel at specific time periods and analyzed using Gas Chromatography-Mass Spectrometry (GCMS). All compound concentrations are displayed in graphs as a percent of the average concentration across all barrels in the experiment.

Results and Discussion

Addition of Smoke Components

Figure 9.1 shows the results after six months of finishing in new barrels that were treated with the proprietary smoking process using apple wood, maple wood and hickory wood. A significant increase in the compounds responsible for smoke character was observed for all three materials.

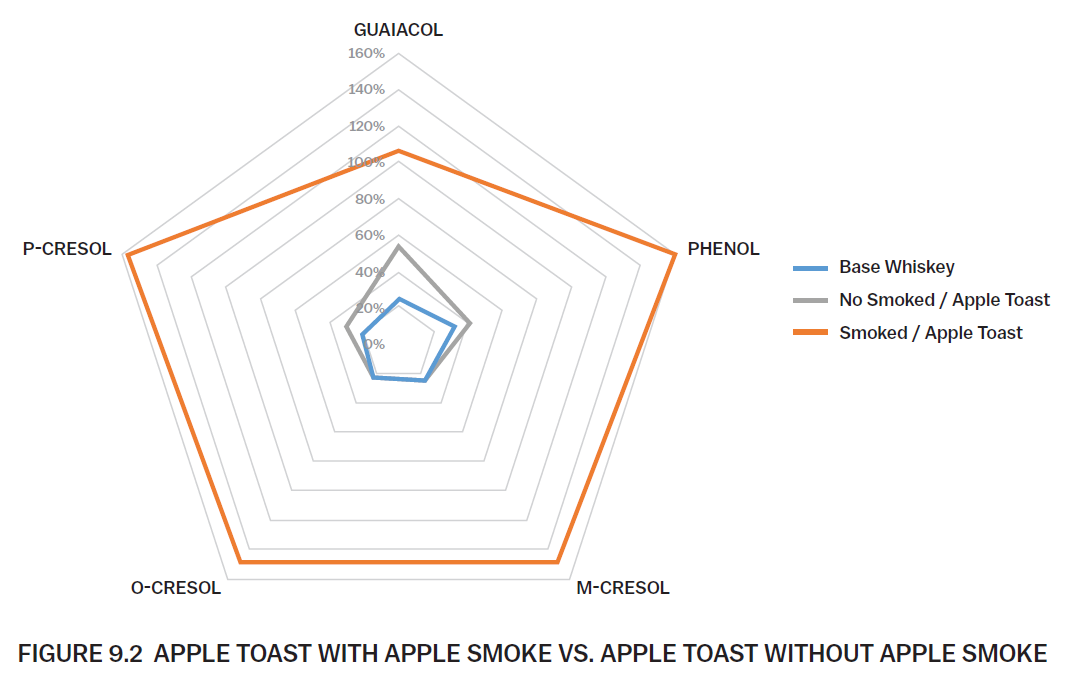

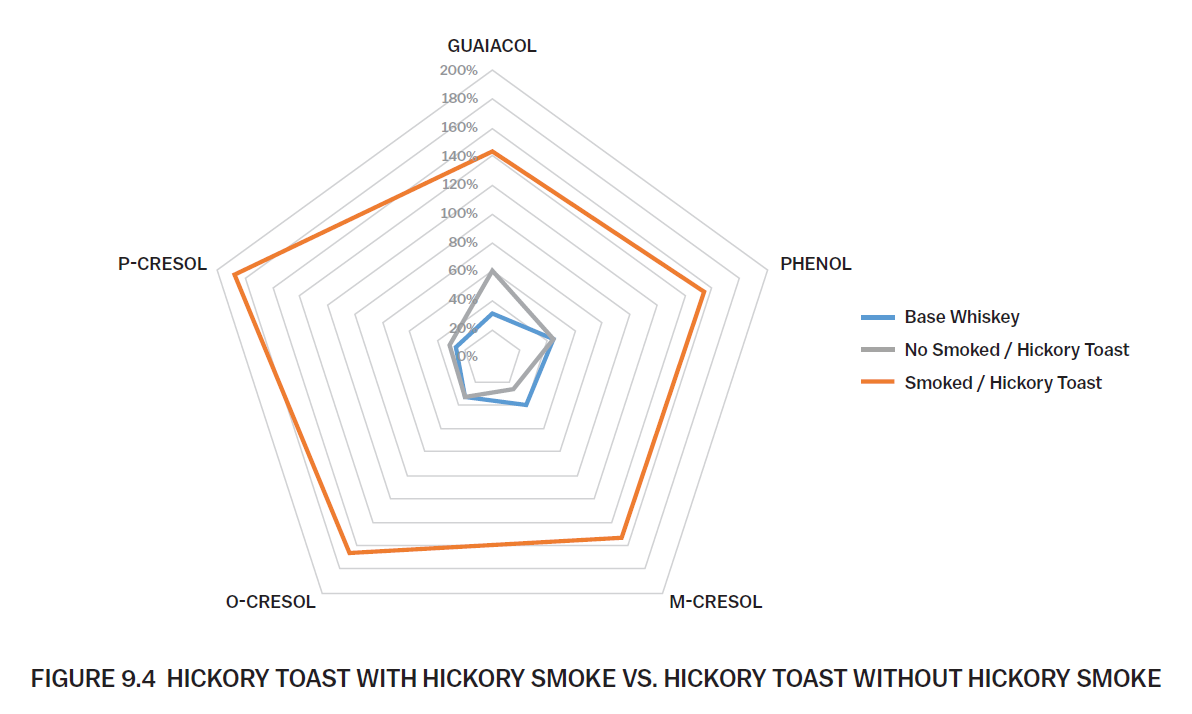

In order to reduce acrid flavors and promote the perception of favorable smoke character, each smoking material (apple, maple, hickory) was paired with a custom toast profile to enhance the respective characters of each material. However, when barrels are toasted, concentrations for smoke components will increase due to the degradation of lignin within the stave. It was important to establish how much of the increase in smoke component concentration was due to the smoking process versus the toasting process. To determine this, identical barrels that were not subjected to the cold smoking process were added to the experiment. This allowed us to clearly define the increase strictly due to the smoking process.

The results from Figures 9.2 through 9.4 confirm the majority of the increase in smoke component concentration in each sample was due to the cold smoking process and not the toasting process.

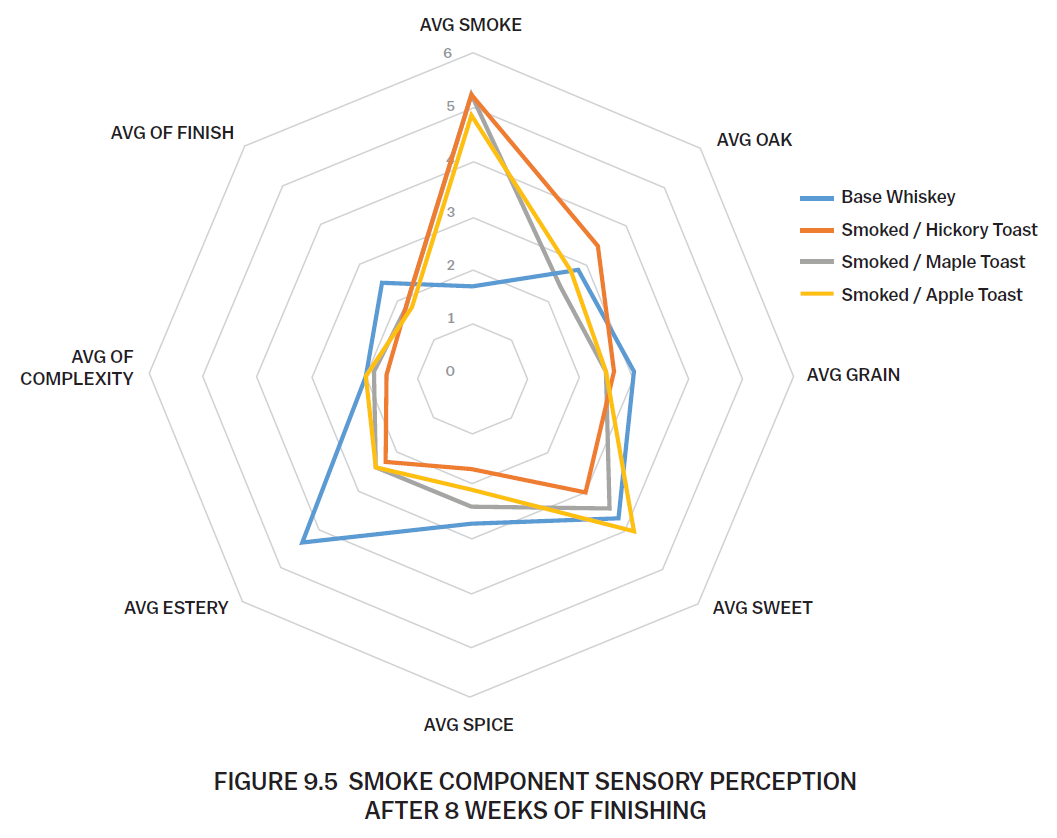

Additionally, sensory analysis performed by our Research Center Sensory Panel confirmed that smoke perception was overwhelmingly apparent after eight weeks of finishing. The eight-week sensory results are displayed in Figure 9.5.

Addition of Barrel Components

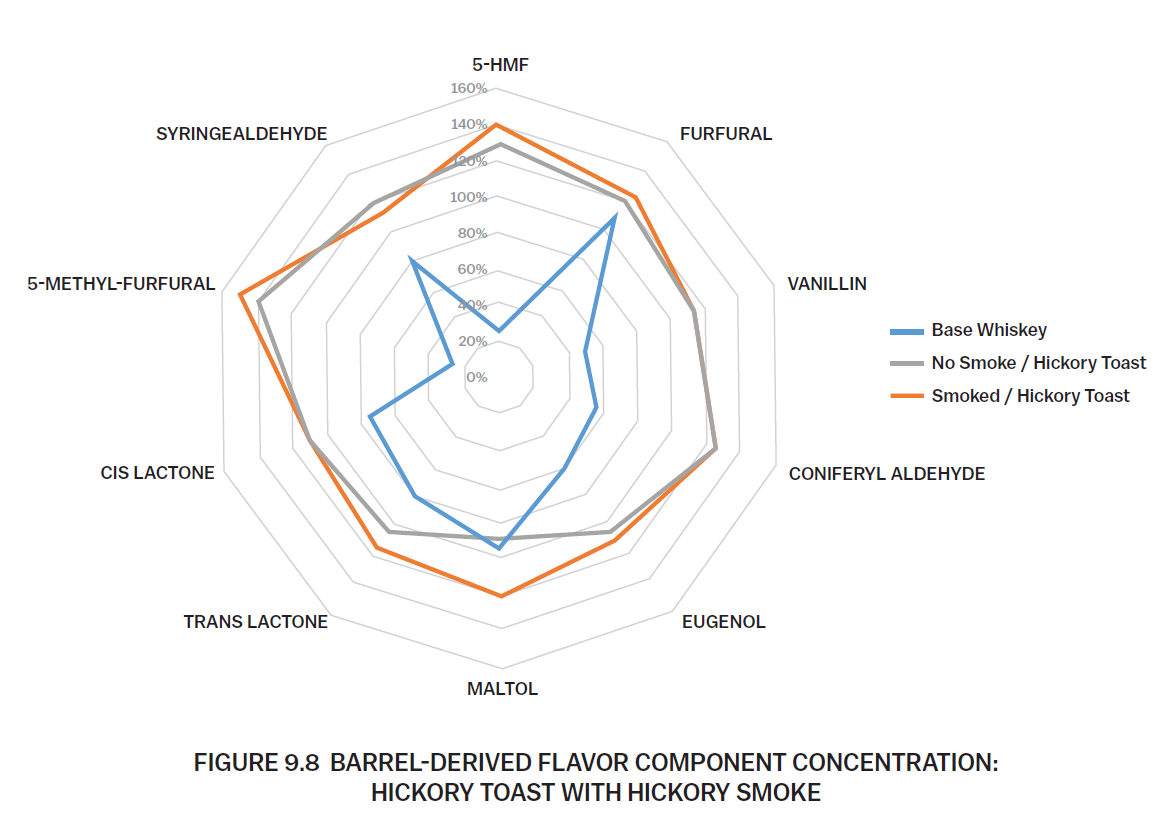

In addition to smoke compound concentration, a significant increase in other barrel flavor compounds were found in all samples after the finishing process. Figures 9.6 through 9.8 display the concentration of barrel-derived flavors for each barrel in the smoked barrel series.

These results confirm the smoking process does not positively or negatively affect the extraction of barrel-derived flavor components. This is important, as the cold smoking process is designed to add smoke character without changing other flavor components concentrations of the toast profile.

Smoke Component Concentration with Respect to Time in Secondary Barrel

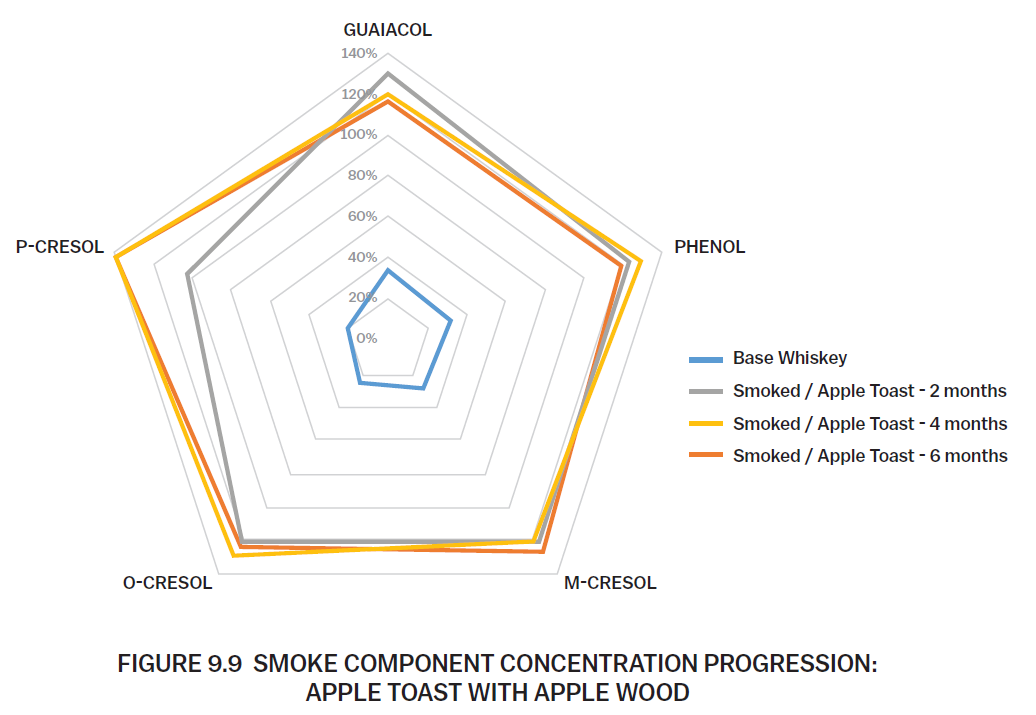

Figure 9.9 shows components responsible for increased smoke character are introduced to the spirit very quickly and concentrations do not significantly change with time. This experiment also demonstrates smoke perception does not decrease for the majority of finishing applications (under six months).

Conclusions

This experiment confirms the viability of our proprietary cold smoking process to provide significant smoke character during finishing applications.

Key findings include:

- Smoke compounds derived from the smoking process are delivered to the spirit above threshold of human perception in as little as two months according to results from sensory analysis.

- ISC's proprietary cold smoking process does not positively or negatively affect the extraction of barrel-derived flavor components. The integrity of the toast profile is maintained; applying the cold smoking process to the barrel will simply add smoke character beyond what would have been expected from the toast profile.

- Smoke component concentration did not significantly change after two months of aging.

- Utilizing toasted barrels significantly increases the barrel extractive concentration during secondary maturation periods.

Books are available through your account manager.