TRIAL 6: Effects of Toasting on Barrel Extractive Concentrations

By Andrew Wiehebrink, Director of Spirit Research and Innovation

Introduction

Toasted spirit barrels are becoming an important tool for producers looking to boost extractive concentration in a short period of time and/or further control the types of flavors delivered to a spirit.

Traditionally, distillers have focused on charred barrels. Charring a barrel is known to do the following: further develop the oak’s flavor potential, create a red layer under the char that will help the spirit develop its color, and add a mellowing element from the char itself. The level of char, typically ranging from 1-4, will add further nuance to the impact of the barrel on the spirit.

Toasting a barrel will take place just before the barrel is charred. The toasting process involves heating the barrel to specific temperatures over time to slowly break down the oak polymers into smaller compounds. At ISC, we have developed many toast profiles using different combinations of time and temperature. Each combination results in a unique sensory profile. This allows for countless variations of flavor extractives to be created according to the distiller’s needs. Distillers may choose toast profiles from those established or develop a custom toast best suited to specific flavor goals. Furthermore, toasting the barrel transforms oak through a larger thickness of the stave than charring allows. This results in an increased concentration of oak extractives available to enhance the aroma, flavor and complexity of barrel-aged spirits. Traditional charring may still be used after the toasting process is complete.

Objective

The purpose of this experiment is to examine the difference in extractive potential during new barrel maturation when utilizing toasted barrels.

Methods

Base Liquid

Variety: New make bourbon distillate

Mash Bill: 75% corn/13% rye/12% malted barley

Entry Proof: 125 proof/62.5% ABV

Trial Execution

Entry Date: June 2016

Primary Maturation Period: 60 months

Warehouse Location: Bardstown, KY

The Trial

New make bourbon distillate filled in the following barrel type:

Four barrels of each variation were included in the experiment.

For the barrels that were toasted, two different toast profiles were selected for this experiment – Spice 1 and Traditional Medium Plus. Each toast profile is based on specific combinations of time and temperature to yield different results, which are explored further in the Results section.

Samples were taken from each barrel at 24 months and 60 months and then analyzed using Gas Chromatography-Mass Spectrometry (GCMS). All compound concentrations are displayed in graphs as a percent of the average concentration across all barrels in the experiment.

Results and Discussion

Toasted Barrel vs. Traditional Charred Barrel

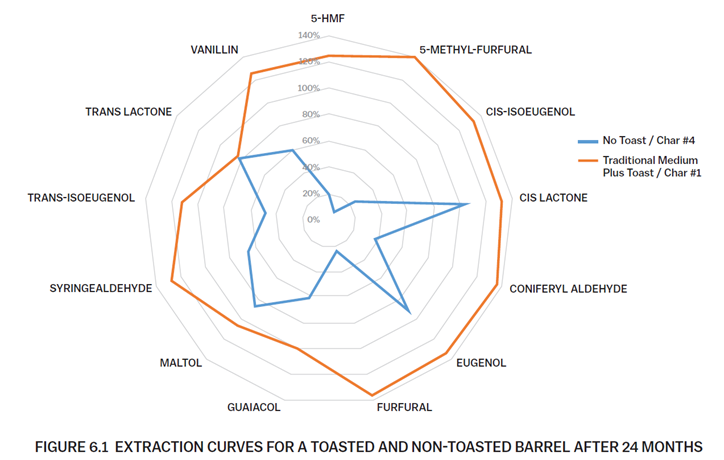

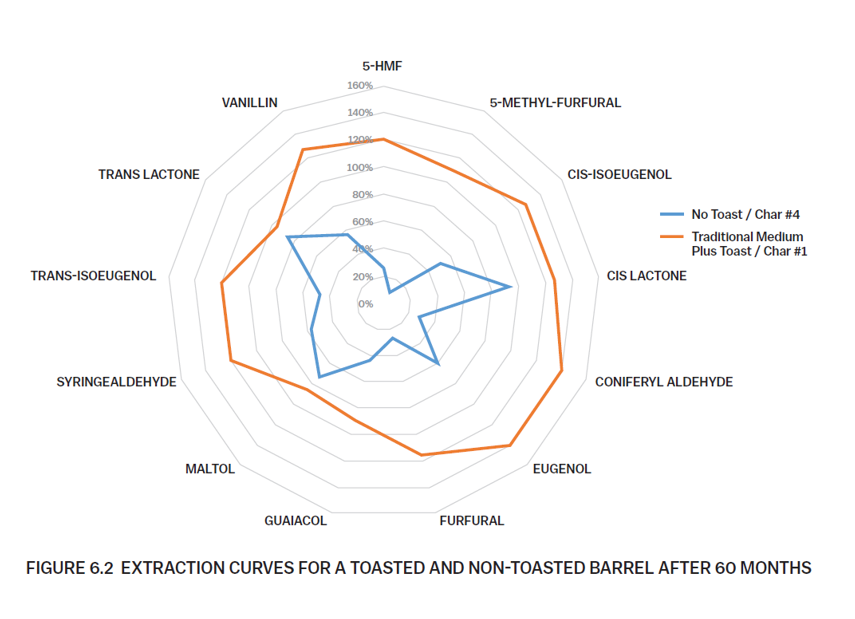

The creation of barrel-derived flavor congeners is a result of the pyrolysis of oak over a given period of time and at a specific intensity of temperature. With a charring process, this time period is very short, and temperatures are very high. With toasting, the time is much longer, up to 60 minutes, and the temperatures targeted are relatively low compared to charring. Most barrel-derived flavor congeners are broken down into smaller compounds at relatively low temperatures, which is why toasting is an ideal method for building higher concentrations of these favorable compounds. Figure 6.1 shows the GCMS data on whiskey taken from a toasted barrel (Traditional Medium Plus) with a Char #1 level and a standard Char #4 barrel without a toast profile after 24 months of aging.

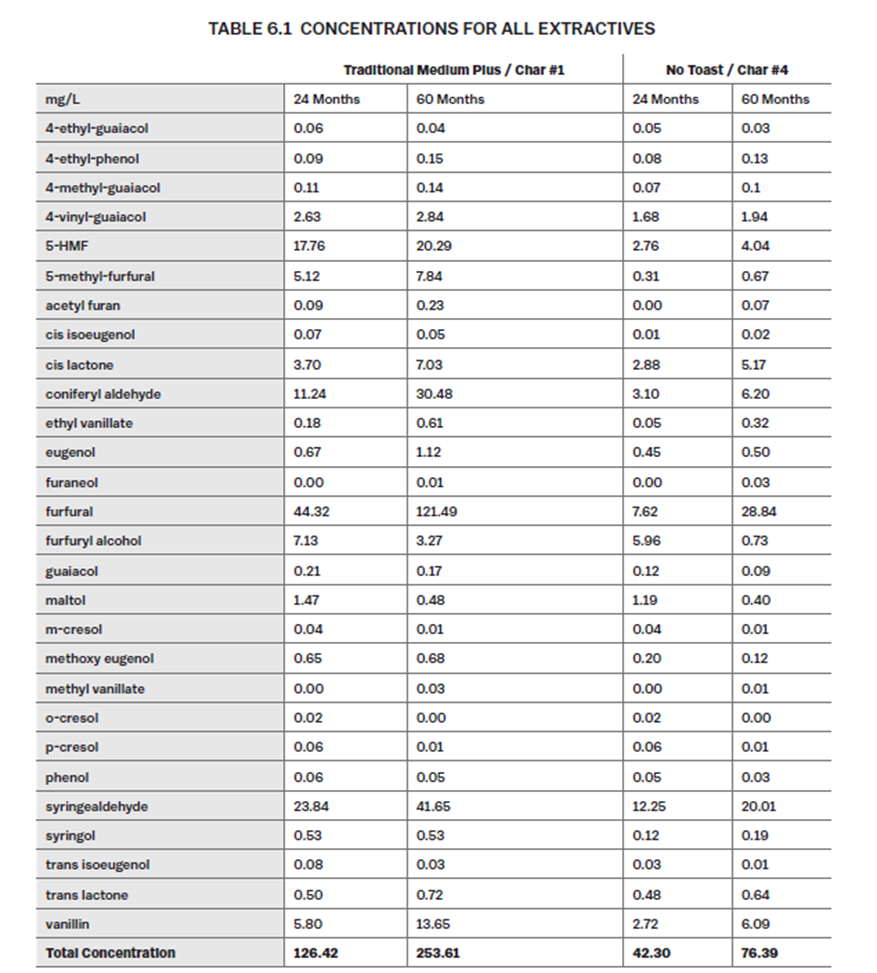

Overall concentration for measured flavor congeners for the Char #4 barrel at 24 months is approximately 42.3 mg/L. Conversely, the concentration of measured congeners for the toasted barrel is 126.4 mg/L. At 60 months, which is presented in Figure 6.2, the concentrations increased to 76.4 mg/L and 253.6 mg/L for the Char #4 barrel and the toasted barrel, respectively. With a percent difference between the two average concentrations of 103% at 24 months, and 113% at 60 months, the discrepancy remained relatively similar through that given aging period. Table 6.1 displays the concentration for all extractives tested.

Difference Between Toast Profiles

A significant advantage of toasting is the high degree of temperature control over a longer period of time than charring can allow. The variables of time and temperature are combined to create highly precise recipes that can target the creation of different barrel-derived flavor congeners in different levels. Some toast profiles will build up high concentrations of specific compounds in the staves; other toast profiles will lead to lower levels or medium levels of certain extractives. Toast profiles may also be developed with a distiller to fit a specific mash bill and maturation regime.

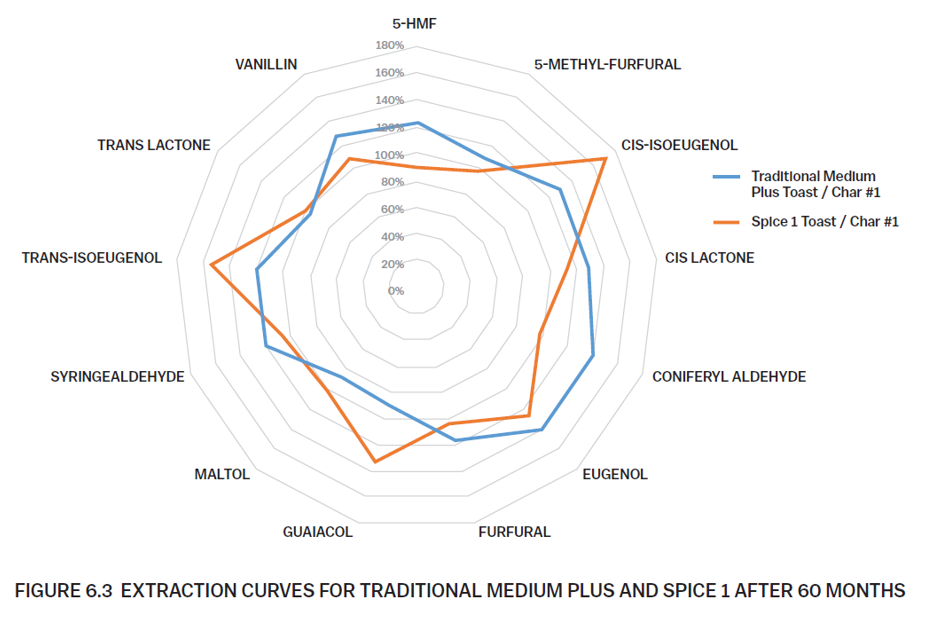

When the intensity of the toast is precisely controlled, there is a high degree of confidence in building concentrations of specific compounds in the staves. Two different ISC toasted barrels from this experiment are shown in Figure 6.3 (both with a Char #1).

Traditional Medium Plus Toast

This toast profile was developed to focus on a balance of popular barrel-derived congeners such as vanillin and the furfural extractives linked to toasty, caramelized flavors. Results in Figure 6.3 confirm a broad range of extractives for a complex and rounded flavor profile.

Spice 1

As the name suggests, this toast profile was developed to focus on spice notes. Results in Figure 6.3 do show an increase in spice flavor compounds compared to the Traditional Medium Plus Toast barrel. Spice 1 demonstrated increases in both cis isoeugenol and trans isoeugenol, as both of these congeners in the eugenol family are described as having spicy aromas.

Conclusions

Heat is a key method for transforming the aromatic and flavor potential of oak barrels, allowing distillers to hone in on the sensory traits most desired for a specific mash bill. This experiment confirmed the increased options available to distillers by toasting a barrel before it is charred.

As expected, the toasted barrels tested during this experiment clearly showed increased extractive concentration compared to barrels that only went through the charring process. This suggests toasting is a useful option for increasing barrel-derived congeners extracted into the aging spirit. Toasting may also be a useful option for increasing the extraction rate in new barrel maturation since the oak is transformed through a deeper portion of the stave.

The experiment also confirmed toasting can be controlled to deliver precise flavor development. Both toasted barrels tested had toasts designed to target a specific flavor balance. GCMS results demonstrated the toasted barrels offered a different balance of extractives from each other, and the results also matched the sensory profile they had been designed to target. Furthermore, the toasted barrels maintained their flavor profile for at least 60 months of aging. This information suggests distillers can not only target a certain profile of barrel-derived flavor congeners, the specific toast profile selected is repeatable and dependable thanks to the high degree of control over the toasting process.

Books are available through your account manager.