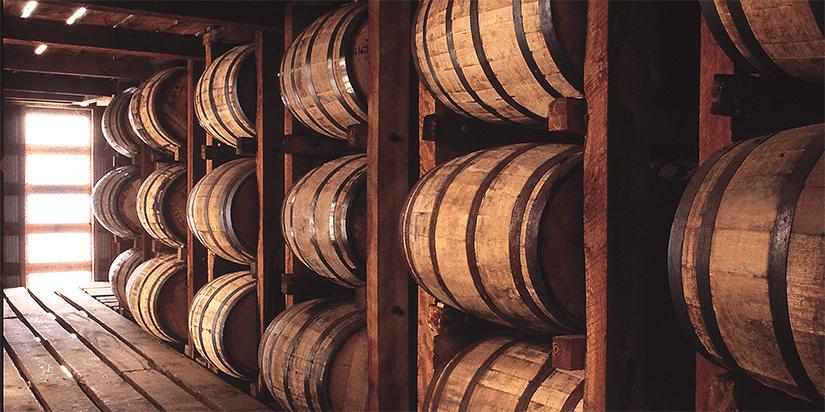

A Formula for Maturation

The thing about crafting good whiskey is it takes a long time – years aging in oak barrels – before it reaches full maturity. Aging whiskey in oak will always be necessary as three very important changes happen while the whiskey sits. These changes all are imperative to craft a great final product. The reactions that happen during the maturation process are very slow and that is why we need time to create a mature and balanced spirit.

1. Extraction

When we char and/or toast a barrel, we change the wood chemistry – creating new, more favorable compounds that will be extracted by the spirit throughout the aging process. Lignin breaks down and forms many flavor compounds, of which the most important by far is vanillin. Hemicellulose breaks down into simple sugars (which caramelize when heat is applied to the barrel), and oak tannins lend color and mouthfeel to the final product.

Now the whiskey must make its way into the barrel and grab hold of these extractives we have created. This process is governed by variations in pressure which are the result of changes in air temperature. Pressure change is directly proportional to temperature change. In other words, a rise in temperature causes expansion which in turn causes a rise in pressure. During the warm summer months, rising pressure in the barrel forces whiskey into the wood and the whiskey comes in contact with these extractives. Then, as the weather turns colder, there is a pressure drop within the barrel and whiskey is pulled back inside bringing the yummy compounds along.

Several factors contribute to this process. Climate, aging environment, barrel size, just to name a few. Climate is arguably one the most influential factors. For example, the climate in Scotland permits the whisky to age about one quarter of the rate of whiskey that ages in Kentucky. In other words, four years in Scotland can be equated to roughly one year of aging in Kentucky.

2. Subtraction

The removal of unfavorable products through filtering is called subtraction. When charred, the interior surface of the barrel becomes a charcoal filter. This filter serves as a roadblock to the undesirable flavors and aromas in the distillate. The longer a barrel is charred, the thicker the char layer becomes. Most bourbon casks have a high char level. However, no matter how thick the layer is, you can’t char a barrel, put whiskey in it, then roll it down a hill and expect all the undesirables to be removed, it takes time.

3. Oxygenation

The final important change to discuss is oxygenation or otherwise known as oxidation. Oak is a ring porous wood which allows the barrel to serve as a gas permeable “membrane.” Oxygen passes through the barrel staves while the barrel stays liquid tight. Oxygenation/oxidation occurs inside the wood slowly and naturally, helping facilitate the maturation process.

Oxygen is needed for the initial oxygenation as well as two key reactions that are important to flavor development – esterification and transesterification, which are connected to fruity character and top note in spirits. Acids created by yeast during fermentation bond with alcohols to create esters. These newly formed esters will combine with alcohols to form different esters (transesterification).

This is not a static process. The esters will continue to recombine throughout distillation and barrel aging. Flavors are continuously created, destroyed, and then replaced with new ones!

In a nutshell, the formula for maturation is:

Extraction + Subtraction + Oxygenation = Maturation

You truly need all three to have a well matured product.

What goes on inside the barrel is, in my opinion, the most fascinating part of making whiskey. Much remains a mystery and I hope we never figure everything out. The allure of whiskey – why one barrel taste different than the one sitting next to it – is what makes it so enjoyable to drink.

About the Author

Andrew Wiehebrink

Andrew joined the ISC team as the head of Research and Development in early 2016. His primary focus is working with ISC customers to develop and test new products. He will also design experiments to gather data on whiskey maturation, barrel performance, process and product innovation.

As a self-described, “bourbon fanatic” Andrew enjoys drinking and studying the history of bourbon. He also owns and operates a farm in Oldham County Kentucky that develops custom corn breeds for use in distilling.

Share this Post