Trial 8: Extraction Study Over 24 Months in a New Oak Double Barrel Application Using Two-Year-Old Bourbon Whiskey

By Andrew Wiehebrink, Director of Spirit Research and Innovation

Introduction

For producers with younger stocks of aged product, double barreling is an efficient way of quickly adding more flavor by increasing the concentrations of favorable barrel extractives in the whiskey. Moreover, double barreling provides a method to differentiate sourced product and quickly create multiple expressions from one liquid stream. By using different treatments on the secondary barrel, it is possible to alter extraction rates and the overall flavor profile.

Objective

For this experiment, the goals are to determine how different barrel treatments affect extractive concentrations and extraction rates as well as to determine how extractive concentrations change over time in a finishing application.

Methods

Base Liquid

Variety: 2-year-old bourbon whiskey

Mash Bill: 75% corn/13% rye/12% malted barley

Entry Proof: 115 proof/57.5% ABV

Trial Execution

Entry Date: April 2019

Secondary Maturation Period: 24 months

Warehouse Location: Oldham, KY (craft racked up to 3 high)

The Trial

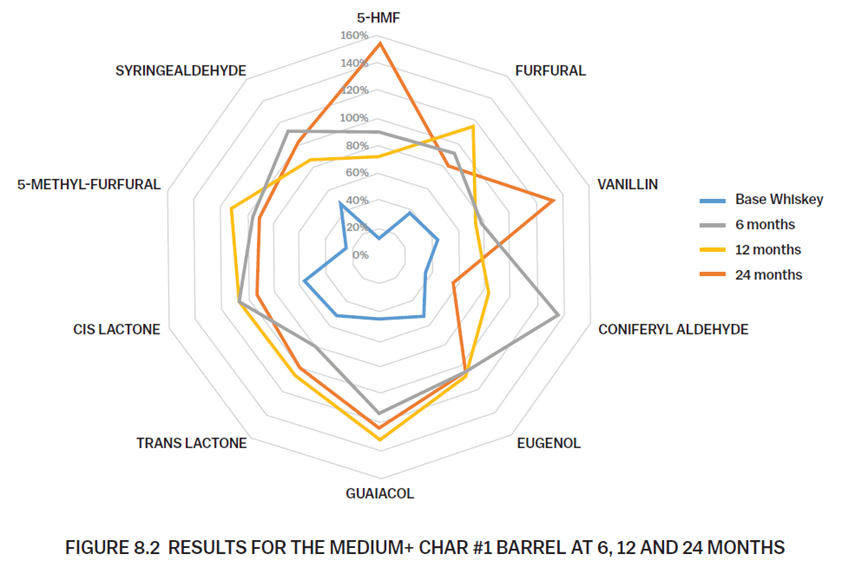

Two-year-old bourbon whiskey which was double barreled for 24 months in the following barrels:

Four barrels of each variation were included in the experiment.

Samples were taken from each barrel every six months and analyzed using Gas Chromatography-Mass Spectrometry (GCMS). All compound concentrations are displayed in graphs as a percent of the average concentration across all barrels in the experiment.

Results and Discussion

In order to facilitate determinations of barrel impact for each barrel treatment, concentrations of ten key flavor components were added together (in mg/L) to create an overall barrel extractive concentration for each barrel treatment at each sampling period. The sum concentration for all compounds in the base whiskey is 35.21 mg/L. It is important to note that this value is not indicative of the flavor profile or overall quality of the sample.

Char #3 Barrel

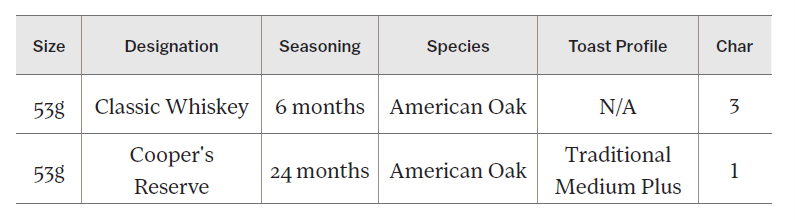

Figure 8.1 displays the results at 6 months, 12 months and 24 months of secondary aging in the Char #3 barrel.

Within the first sampling period of six months, the Char #3 barrel displayed increases in most of the barrel extractives tested. It is noteworthy that in the case of certain extractives including furfural, guaiacol, and 5-MF, concentrations decreased. This subtractive effect has been documented in previous experiments1 that ISC has conducted involving double barreling with heavier charred barrels.

After 6 months in the Char #3 barrel, the overall sample concentration is 61.60 mg/L, which represents a 75% increase from the base whiskey. After 12 months, the overall concentration of barrel extractives decreased to 53.14 mg/L. Notable decreases include coniferyl aldehyde (11.37 mg/L to 5.71 mg/L) and syringaldehyde (24.72 mg/L to 18.66 mg/L). Concentrations increased during the period of 12 to 24 months in barrel to 65.48 mg/L. This represents a 4.68% increase from the 6-month sample value.

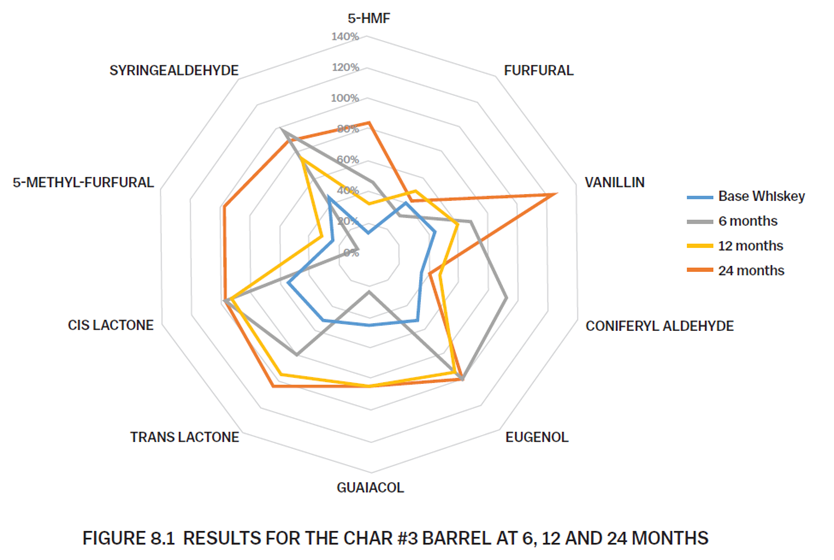

Traditional Medium Plus Char #1 Barrel

By altering the heat and seasoning treatment on the barrel, the extraction rate is changed considerably. Figure 8.2 shows the results through the same time period of 24 months. Unlike the Char #3 barrel, this barrel is toasted (Traditional Medium Plus) and is accompanied with a Char #1. This barrel is also made with oak that has been seasoned for 24 months, which is longer than what is most commonly used for spirit barrels. Toasting and extended seasoning times often increase the amount of extractives available to the spirit.

Compared to the base whiskey, all samples showed large increases in barrel extractive concentration. In 50% of compounds tested, the 12-month sample had the highest concentration. For 50% of the compounds tested, the 24-month sample had the lowest concentration of all samples. Overall concentration of key barrel extractives at 6 months was 95.66 mg/L. This represents a 171.68% increase over the base whiskey and 55.29% over the concentration of the Char #3 double barrel application at 6 months.

Concentrations at 12 and 24 months decreased to 87.11 mg/L and 89.64 mg/L respectively. It is also noteworthy that both the Char #3 and Medium Plus toasted barrels displayed not only different extraction rates, but very different overall flavor profiles.

Conclusions

This experiment sought to confirm the efficiency of the double barreling method to help maximize barrel extractives while also exploring the impact of extended seasoning and charring/toasting levels. The results offer key insights that may be of great use to distillers seeking increased barrel extractive concentration:

- The charred layer of the secondary barrel can reduce the concentration of barrel extractives in the base product, likely by means of chemical absorption.

- The amount of time needed in a secondary barrel to significantly increase the extractive concentration is highly dependent on the type of barrel utilized.

- Toasted barrels generally have a higher concentration of key flavor congeners.

It is also encouraging for distillers who are seeking to maximize flavor quickly that the largest change in extractive concentrations occurred within the first six months of this experiment. This suggests the flavor profile of a spirit may be further boosted or adjusted without an extensive time delay.

Books are available through your account manager.