Toasted Barrels Take a Leap into the Future with ISC’s Proprietary Infrared Toasting Technology

Andrew Wiehebrink, Director of Spirit Research and Innovation

For centuries, distillers and winemakers have relied on the nuanced flavors of toasted oak to bring extra depth and complexity to their products. While toasted barrels have long had a heavy presence in the wine industry, over the past 10 to 15 years the toasting process has become increasingly prevalent in spirit barrels, especially those destined to mature American whiskeys like bourbon and rye.

Both traditional fire and infrared (IR) toasting methods aim to achieve the same goal: to provide distillers with not only an extra boost of flavor, but also a controlled and predictable one. You see, toasting is really about precise flavor addition, rather than overall extractive impact alone. That’s not to say it’s wrong to use a heavy toast and load the whiskey up with as much extractive potential as possible, as many producers do that successfully. However, by taking a more targeted approach to the toast profile, the distiller can layer flavors exactly as he or she envisioned them. This means that whatever your aging goals may be, a well-planned toast can help you get there more efficiently and with better results.

With progress comes higher expectations. Over the past decade, we’ve seen orders for toasted spirit barrels rise dramatically, and we have worked hard to expand our capacity to meet this demand. Meanwhile, behind the scenes, we’ve also been developing a new frontier: our proprietary IR toasting pots. As the global spirits market becomes more competitive, distillers of all sizes expect tighter flavor standards and better barrel-to-barrel consistency.

What Does Performance Mean to Us?

From day one, our goal was never to create a machine that strayed from the flavor delivery of traditional pot toasting. Quite the contrary… our aim was reducing difference in flavor delivery. We focused on creating a better working environment, achieving more energy-efficient processes, and, most importantly, delivering better barrel-to-barrel flavor consistency.

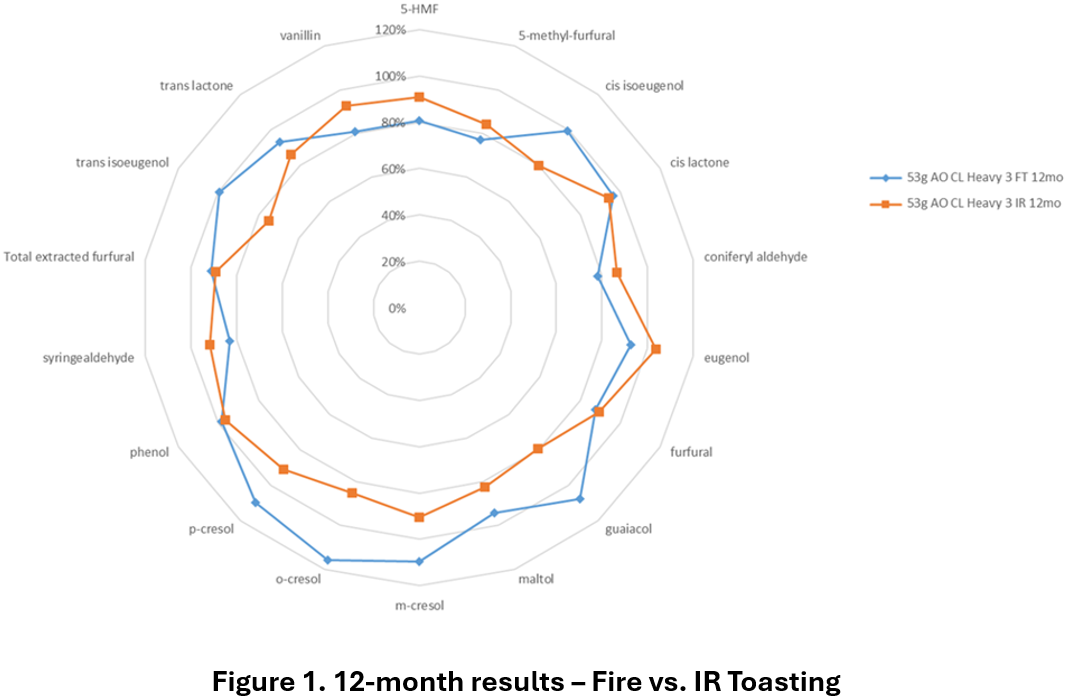

Our first IR vs. fire toasting barrel experiment has been aging for just over two years, and I am pleased with the results so far. Figure 1 below shows the differences observed between the two methods when the overall barrel treatment remained the same — same char level, same seasoning, and same toast profile; the only variable was the toasting method. The results represent 4-barrel composites for each variant.

As you can see, both variants exhibit very similar overall flavor profiles (the shape of the spider plots is relatively the same). The key difference lies in smoky/phenolic markers, particularly the cresols and guaiacol. The higher levels in the fire-toasted barrels are directly associated with smoke from the pots of burning oak being absorbed into the staves.

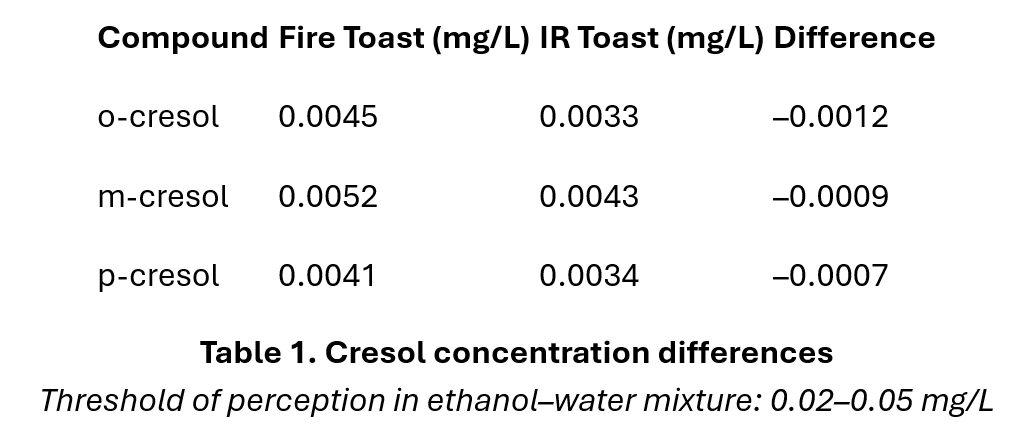

Cresols can be very acrid, so a reduction is generally viewed as positive for overall flavor quality. However, it’s worth noting that the differences observed here are likely not perceptible, as concentrations in both variants are well below the threshold of perception in model spirits [1]. See Table 1 for details.

Our two-year samples are already at our company lab in Napa, California, awaiting analysis. Check back here in a few months for an update on the progress of this experiment, as well as more insights on how these two methods compare in terms of barrel-to-barrel consistency.

Questions about toast profiles and flavor development in your distilled spirits? Email me to discuss your unique barrel solutions.

Andrew Wiehebrink

R&D Spirits Division